MAIKONG’s state-of-the-art manufacturing facility in Nigeria

Our comprehensive product range includes every critical component for all major pellet machine types. Whether you operate feed pellet machines, wood pellet machines, fertilizer pellet machines, or complete pellet production lines, MAIKONG delivers the exact pellet machine parts you need to maintain peak performance.

Experience the MAIKONG Difference

With 20+ years of expertise in pellet machine manufacturing, we understand what Nigerian businesses need to succeed.

Learn More About MAIKONG

Critical Pellet Machine Parts and Their Functions

Understanding the role of each component in your pellet machine helps you identify potential issues before they cause costly downtime. Here’s a breakdown of the most essential pellet machine parts and their functions:

Die and Roller Assembly: The Heart of Your Pellet Machine

The die and roller assembly is where the actual pellet formation occurs. This critical system experiences the most wear and requires the highest quality materials and precision manufacturing.

Flat Dies and Ring Dies

Dies are the hardened metal plates with precisely engineered holes through which material is forced to create pellets. MAIKONG manufactures both flat dies and ring dies using premium alloy steel with specialized heat treatment for maximum durability. Our dies feature:

- Precision-engineered hole patterns optimized for different materials

- Superior wear resistance with service life up to 2000 hours

- Customizable compression ratios for different materials

- Uniform hole distribution for consistent pellet quality

Need a Custom Die for Your Specific Material?

MAIKONG engineers can design a die with the optimal hole pattern and compression ratio for your specific application.

Discuss Your Requirements on WhatsApp

Press Rollers: Delivering Consistent Pressure

Rollers work in conjunction with the die to compress raw materials into pellets. These components must withstand enormous pressure while maintaining precise tolerances. MAIKONG rollers feature:

- Hardened alloy steel construction with 55-60HRC hardness

- Precision-balanced design to minimize vibration

- Specialized surface treatment for improved material grip

- Extended service life of up to 1500 hours

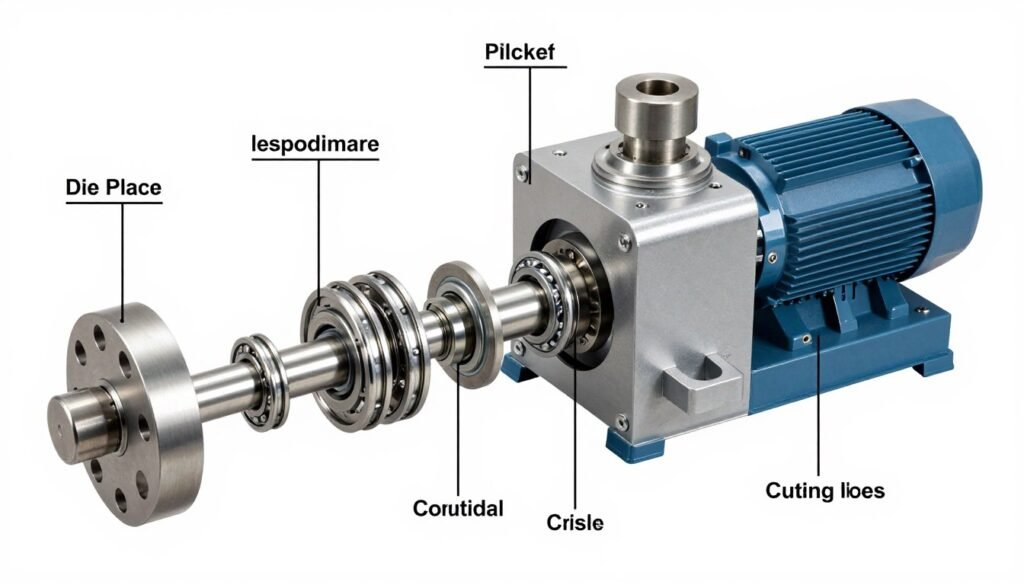

Transmission System: Power and Precision

The transmission system transfers power from the motor to the pelletizing components. Reliability here is essential for consistent operation and preventing costly breakdowns.

Gearbox and Bearings

MAIKONG gearboxes and bearings are engineered for the heavy loads and continuous operation typical in pellet production:

- Heavy-duty gearboxes with hardened gears for maximum torque transfer

- Sealed bearing systems that prevent dust contamination

- Optimized lubrication systems for reduced heat generation

- Reinforced housings that minimize vibration and noise

Cutting System: Precise Pellet Length Control

The cutting system determines the length of your pellets, which affects both their quality and their behavior during handling and storage:

- Hardened steel knives with precision-ground cutting edges

- Adjustable cutting mechanisms for different pellet lengths

- Balanced design to prevent vibration during operation

- Quick-change systems for minimal maintenance downtime

Selecting the Right Pellet Machine Parts for Your Operation

Choosing the correct pellet machine parts involves understanding both your equipment specifications and your production requirements. MAIKONG experts can help you identify the optimal components for your specific situation.

Factors to Consider When Selecting Replacement Parts

| Factor |

Considerations |

MAIKONG Advantage |

| Material Type |

Different materials (wood, feed, fertilizer) require specific die and roller configurations |

Custom-engineered parts optimized for specific Nigerian raw materials |

| Production Volume |

Higher volumes require more durable components with longer service life |

Industrial-grade components designed for continuous operation |

| Operating Conditions |

Temperature, humidity, and dust levels affect component selection |

Parts engineered specifically for Nigerian environmental conditions |

| Machine Model |

Parts must match exact specifications of your equipment |

Comprehensive inventory of parts for all major pellet machine models |

| Maintenance Schedule |

Preventive replacement schedules maximize uptime |

Detailed maintenance guidelines and technical support |

Not Sure Which Parts You Need?

Our technical team can help identify the exact components for your specific machine model and application.

Email Our Technical Team

The MAIKONG Quality Advantage in Pellet Machine Parts

What sets MAIKONG pellet machine parts apart from alternatives in the Nigerian market? Our commitment to quality at every stage of the manufacturing process:

MAIKONG Quality Standards

- Premium alloy steel with optimal hardness ratings

- Vacuum heat treatment for superior wear resistance

- CNC precision manufacturing with tight tolerances

- 100% quality inspection before shipping

- Comprehensive testing under load conditions

- Parts designed specifically for Nigerian operating environments

Common Issues with Generic Parts

- Inconsistent material quality leading to premature failure

- Poor dimensional accuracy causing operational issues

- Inadequate heat treatment resulting in rapid wear

- Limited or no technical support

- Incompatibility with specific machine models

- Short service life increasing overall operating costs

Material Selection and Engineering

MAIKONG selects only the highest grade materials for our pellet machine parts, with specific alloys chosen based on the component’s function and operating conditions:

- Dies manufactured from X46Cr13 or equivalent high-carbon, high-chromium steel

- Rollers produced using specialized wear-resistant alloys with optimal hardness differential to the die

- Bearings selected from premium suppliers with specific load ratings for pellet machine applications

- Gearbox components manufactured from case-hardened alloy steels for maximum durability

Experience the Quality Difference

MAIKONG parts typically last 30-50% longer than generic alternatives, reducing your total cost of ownership.

Request a Quote Today

Maintenance Guide: Maximizing Pellet Machine Part Lifespan

Proper maintenance not only extends the life of your pellet machine parts but also ensures consistent pellet quality and production efficiency. Follow these MAIKONG-recommended maintenance practices:

Daily Maintenance Checklist

- Inspect die and roller surfaces for signs of uneven wear or damage

- Check bearing temperatures during operation (should not exceed manufacturer specifications)

- Monitor amperage draw to detect potential issues before failure

- Ensure proper lubrication of all moving components

- Clean accumulated material from die face and roller surfaces

Signs Your Pellet Machine Parts Need Replacement

Recognizing these warning signs early can prevent catastrophic failures and minimize downtime:

Die Replacement Indicators

- Decreased production output despite normal operating conditions

- Inconsistent pellet quality or density

- Visible enlargement or irregular wear of die holes

- Increased power consumption during operation

- Reaching the recommended service hour threshold (typically 1500-2000 hours)

Roller Replacement Indicators

- Visible flat spots or uneven wear on roller surfaces

- Increased vibration during operation

- Unusual noise from the pelletizing chamber

- Decreased material grip leading to slippage

- Reaching the recommended service hour threshold (typically 1000-1500 hours)

Pro Tip: Keep detailed records of operating hours for each component to predict replacement needs and schedule maintenance during planned downtime rather than experiencing unexpected failures.

Need Maintenance Support?

MAIKONG offers technical support via WhatsApp to help you diagnose issues and implement proper maintenance procedures.

Contact Technical Support

Customized Pellet Machine Parts for Nigerian Operations

Every pellet production operation has unique requirements based on raw materials, production goals, and operating conditions. MAIKONG specializes in creating customized pellet machine parts optimized for specific Nigerian applications.

Common Customization Options

| Component |

Customization Options |

Benefits |

| Dies |

Hole diameter, pattern, compression ratio, material grade |

Optimized for specific raw materials, improved pellet quality, increased production efficiency |

| Rollers |

Surface pattern, diameter, hardness, material composition |

Better material grip, reduced slippage, extended service life |

| Cutting System |

Blade configuration, adjustment mechanism, material grade |

Precise pellet length control, cleaner cuts, reduced fines |

| Gearbox |

Gear ratio, cooling system, lubrication method |

Optimized power transfer, reduced heat generation, improved reliability |

The Customization Process

MAIKONG’s engineering team works closely with clients to develop pellet machine parts that address their specific challenges:

- Consultation to understand your specific requirements and challenges

- Analysis of your current operation, raw materials, and production goals

- Engineering design of customized components with 3D modeling

- Prototype development and testing when necessary

- Production using premium materials and precision manufacturing

- Quality testing under simulated operating conditions

- Installation support and performance verification

Need Custom Parts for Your Specific Application?

Our engineering team can design components optimized for your unique requirements.

Start Your Custom Order

How to Order MAIKONG Pellet Machine Parts

Getting the right pellet machine parts for your operation is simple with MAIKONG’s streamlined ordering process:

Ordering Process

- Identify Your Needs: Determine which parts you need based on your machine model and specific requirements

- Contact MAIKONG: Reach out via email, WhatsApp, or our website contact form

- Technical Consultation: Our experts will verify compatibility and recommend optimal solutions

- Quotation: Receive a detailed quote with pricing, specifications, and delivery timeline

- Order Confirmation: Approve the quote and confirm your order

- Production: Your parts are manufactured to exact specifications

- Quality Inspection: Every component undergoes rigorous testing

- Delivery: Parts are carefully packaged and shipped to your location in Nigeria

- Installation Support: Technical guidance for proper installation when needed

What information do I need to provide when ordering parts?

To ensure you receive the exact parts you need, please provide:

- Machine make and model

- Part numbers (if available)

- Material being processed

- Current production challenges or goals

- Photos of existing parts when possible

How long does delivery take within Nigeria?

Standard delivery for in-stock items is typically 3-5 business days to major Nigerian cities. Custom-manufactured parts generally require 10-15 business days plus shipping time. Expedited options are available for urgent requirements.

Do you offer installation services?

Yes, MAIKONG provides professional installation services for complex components. Our technicians can travel to your facility to ensure proper installation and initial operation. For standard parts, we provide detailed installation instructions and technical support via WhatsApp.

Ready to Order Quality Pellet Machine Parts?

Contact MAIKONG today to discuss your requirements and experience our exceptional service.

Why Choose MAIKONG for Your Pellet Machine Parts

When you choose MAIKONG for your pellet machine parts, you’re partnering with Nigeria’s leading specialist with over 20 years of experience in the industry. Our commitment to quality, reliability, and customer satisfaction has made us the preferred supplier for businesses throughout Nigeria.

4.9

Customer Satisfaction

Delivery Reliability

4.7/5

From individual components to complete pellet machine systems, MAIKONG delivers the quality, reliability, and support that Nigerian businesses depend on. Contact us today to discuss your pellet machine parts requirements and discover why we’re Nigeria’s trusted partner for pellet production success.

Start Improving Your Pellet Production Today

Contact MAIKONG for expert advice and quality pellet machine parts that deliver results.

Contact Us Now