pelleting machine price in nigeria ,animal feed pellet machine

Diesel Engine Pellet Machine: Best Choice for Areas with Poor Electricity

December 27, 2025

Facing electricity challenges in your pellet production? Contact our technical team today for a consultation.

Facing electricity challenges in your pellet production? Contact our technical team today for a consultation.

What is a Diesel Engine Pellet Machine?

A Diesel Engine Pellet Machine is a specialized equipment designed to produce high-quality pellets from various raw materials without relying on electricity. Instead of electric motors, these machines utilize diesel engines as their power source, making them ideal for operations in areas with limited or unreliable electricity access.

MAIKONG’s D-type Diesel Engine Pellet Machine in operation

How Diesel Pellet Mills Work

The diesel engine powers a mechanical system that processes raw materials through a die and roller assembly. As the die rotates (in die-turned models) or as the rollers rotate (in roller-turned models), the raw material is compressed through die holes to form uniform, dense pellets. The entire process operates independently of electrical power, ensuring continuous production even during power outages.

Die-Turned Diesel Pellet Mills

In die-turned models, the flat die rotates while the rollers remain stationary. The rotating die distributes the raw material evenly to be compressed by the rollers into the die holes, forming pellets of uniform size and density.

Roller-Turned Diesel Pellet Mills

Roller-turned models feature rotating rollers and a stationary die. The rollers compress the raw materials against the die, forcing the material through the die holes to form pellets. These models typically produce pellets with higher density and smoother surfaces.

Internal mechanism showing how raw materials are compressed into pellets

Key Benefits of Diesel Engine Pellet Machines for Nigerian Businesses

Independence from Electricity

The primary advantage of a diesel engine pellet machine is its complete independence from the electrical grid. In Nigeria, where power outages are common, this independence ensures continuous production without interruptions, significantly improving operational efficiency and reliability.

Mobility and Flexibility

MAIKONG diesel pellet machines are designed for easy transportation, allowing you to process raw materials directly at their source. This mobility reduces transportation costs and improves overall efficiency, especially for agricultural operations spread across different locations.

Cost-Effective Operation

Despite the initial investment, diesel pellet machines offer significant long-term savings. They eliminate the costs associated with unreliable electricity, including production delays, damaged equipment, and the need for expensive backup power systems.

MAIKONG diesel pellet machine operating in a remote location without electricity access

Advantages of Diesel Engine Pellet Machines

- Operates independently of electrical grid

- Continuous production during power outages

- Mobile and can be used in remote locations

- Lower operational costs in areas with expensive electricity

- Robust construction for harsh environments

- Simple maintenance requirements

- Versatile raw material processing capabilities

Considerations

- Higher initial fuel costs compared to electricity

- Requires regular diesel supply

- Engine maintenance needs

- Noise levels higher than electric models

- Environmental considerations of diesel emissions

Calculate Your ROI with MAIKONG Diesel Pellet Machines

Our technical team can help you calculate the return on investment for switching to diesel-powered pellet production in your specific operation.

Applications of MAIKONG Diesel Engine Pellet Machines in Nigeria

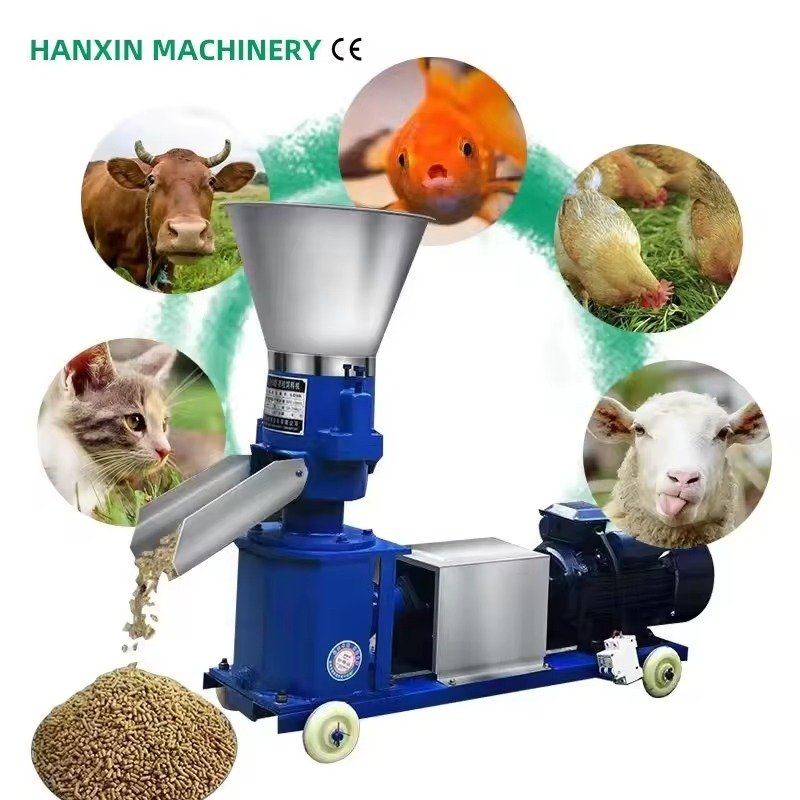

Various pellet types produced by MAIKONG machines: animal feed, wood, and fertilizer pellets

Animal Feed Production

MAIKONG diesel pellet machines excel in producing high-quality animal feed pellets for poultry, cattle, fish, and other livestock. Our machines can process various raw materials including grains, agricultural by-products, and protein sources to create nutritious, easy-to-store feed pellets.

Popular models: Poultry Feed Pellet Machine, Cattle Feed Pellet Machine, Fish Feed Pellet Machine

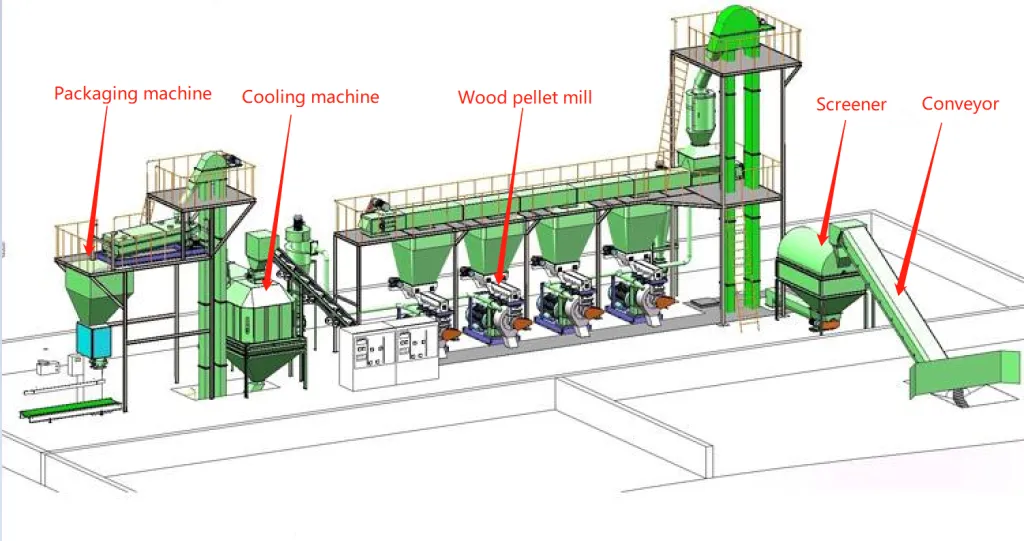

Biomass Fuel Production

Convert agricultural waste and wood materials into valuable biomass fuel pellets using our diesel engine pellet machines. These pellets serve as an eco-friendly alternative to traditional fuels, providing efficient heating and energy solutions while reducing waste.

Popular models: Wood Pellet Machine, Straw Pellet Machine, Sawdust Pellet Mill

Organic Fertilizer Production

Transform organic waste into valuable fertilizer pellets that improve soil quality and crop yields. Our diesel pellet machines process compost, manure, and other organic materials into easy-to-apply fertilizer pellets that release nutrients gradually.

Popular models: Fertilizer Pellet Machine, Organic Waste Pellet Machine

“We switched to MAIKONG’s diesel engine pellet machine after struggling with constant power outages. Our production has increased by 40% since we no longer have to stop operations during blackouts. The machine has paid for itself within 8 months.”

Technical Specifications of MAIKONG Diesel Engine Pellet Machines

Technical diagram of MAIKONG D-type diesel engine pellet machine

| Model | Engine Power (HP) | Capacity (kg/h) | Die Diameter (mm) | Weight (kg) | Dimensions (mm) |

| MKDPM-150A | 8 | 50-100 | 150 | 180 | 1000×500×750 |

| MKDPM-200A | 15 | 80-120 | 200 | 210 | 1460×750×900 |

| MKDPM-230A | 22 | 120-200 | 230 | 280 | 1560×850×1000 |

| MKDPM-260A | 30 | 160-250 | 260 | 330 | 1200×500×1070 |

| MKDPM-300A | 41 | 250-400 | 300 | 410 | 1220×600×1000 |

Raw Materials Compatibility

MAIKONG diesel engine pellet machines are designed to process a wide range of raw materials, making them versatile for various applications in Nigeria:

Wood-Based Materials

- Wood chips and sawdust

- Wood shavings

- Bamboo waste

- Paper waste

Agricultural Residues

- Rice husks and straw

- Corn stalks

- Peanut shells

- Cassava waste

Other Materials

- Cotton stalks

- Bagasse

- Palm kernel shells

- Coconut shells

Various raw materials compatible with MAIKONG diesel engine pellet machines

Material Preparation Requirements

For optimal operation and pellet quality, raw materials should be:

- Sized to 3-6mm particles

- Moisture content between 14-21%

- Free from metal, stones, and other contaminants

MAIKONG offers complementary equipment such as hammer mills and dryers to help prepare your raw materials for pelleting.

Why Choose MAIKONG Diesel Engine Pellet Machines?

MAIKONG’s state-of-the-art manufacturing facility

20+ Years of Expertise

With over two decades of specialized experience in developing and manufacturing pellet machines, MAIKONG has refined our designs to meet the specific challenges faced by Nigerian businesses. Our deep understanding of local conditions ensures that our diesel engine pellet machines deliver exceptional performance in Nigeria’s unique environment.

Customization Options

We understand that every business has unique requirements. MAIKONG offers extensive customization options for our diesel pellet machines, including die hole sizes, engine specifications, and production capacity adjustments. We can tailor our machines to process specific raw materials common in Nigeria.

Comprehensive Support

MAIKONG provides end-to-end support, from initial consultation to installation, training, and ongoing technical assistance. Our WhatsApp technical support ensures you can quickly resolve any issues and maximize your machine’s performance and lifespan.

MAIKONG’s technical support team providing real-time assistance via WhatsApp

How much diesel does a MAIKONG pellet machine consume per hour?

Diesel consumption varies by model and production capacity. On average, our machines consume between 1-3 liters per hour depending on the workload and model size. The MKDPM-200A, for example, consumes approximately 1.5 liters per hour at full capacity, making it highly efficient for its output range.

Can MAIKONG diesel engine pellet machines process multiple types of raw materials?

Yes, our machines are designed to be versatile. With appropriate die configurations, a single machine can process various raw materials including wood waste, agricultural residues, and feed ingredients. However, for optimal performance and pellet quality, we recommend using dies specifically designed for your primary raw material type.

What maintenance is required for MAIKONG diesel engine pellet machines?

Regular maintenance includes diesel engine servicing (oil changes, filter replacements), die and roller inspection, and lubrication of moving parts. We provide detailed maintenance schedules with each machine and offer training for your staff. Most maintenance procedures are simple and can be performed by your team with basic tools.

Business Opportunities with MAIKONG

MAIKONG distributor meeting with clients in Lagos, Nigeria

Become a Distributor

Join MAIKONG’s distribution network and represent our premium diesel engine pellet machines in your region. We provide comprehensive support, including marketing materials, technical training, and competitive pricing structures to help you succeed.

OEM Partnerships

MAIKONG offers OEM manufacturing services for businesses looking to develop their own branded pellet machine line. With our manufacturing expertise and your market knowledge, we can create customized solutions that meet your specific requirements.

Direct Purchase

Purchase MAIKONG diesel engine pellet machines directly for your business operations. We offer competitive pricing, installation support, and comprehensive after-sales service to ensure your investment delivers maximum value.

Customization options available for MAIKONG diesel engine pellet machines

Contact MAIKONG Today

MAIKONG technical team providing on-site installation support

Get Expert Advice

Our technical team is ready to help you select the right diesel engine pellet machine for your specific needs. We can provide detailed information about machine specifications, raw material compatibility, production capacity, and customization options.

Contact us today to discuss your requirements and discover how MAIKONG diesel pellet machines can transform your business operations in Nigeria’s challenging electricity environment.

+86 135 1090 7401WhatsApp/Phone

Ready to Overcome Nigeria’s Electricity Challenges?

Contact MAIKONG today to learn how our diesel engine pellet machines can ensure continuous production regardless of power outages.

Contact us online by Whatsapp: