pelleting machine price in nigeria ,animal feed pellet machine

Choosing the Best Feed Pellet Making Machine in South Africa – 20+ Years Industry Insights

CATEGORY AND TAGS:pellet machine, animal feed pellet machine, feed pellet machine, feed pellet making machine, pelleting machine price in nigeria enquiry

- Specifications

1. Introduction: Why Feed Pellet Machines Are Essential for Nigeria Farmers

In Nigeria, feed pellet machines have become indispensable tools for modern farmers. Our MAIKONG machines transform raw feed materials into compact, nutrient-rich pellets, delivering three key advantages: cost-efficiency, nutrition retention, and waste reduction. By pelleting, farmers slash feed costs by up to 30% through reduced spoilage and optimized ingredient use. The high-temperature process preserves proteins and vitamins, ensuring livestock receive balanced nutrition. Moreover, pellets minimize dust and spillage, cutting waste by 15–20% compared to loose feed. For poultry, dairy, and aquaculture farms, our machines are the backbone of sustainable, profitable operations.

2. Understanding Feed Pellet Machines: Types and Working Principles

Feed pellet machines fall into two main categories based on die design and processing methods. Below is a detailed comparison:

| Feature | Flat-Die Pellet Mill | Ring-Die Pellet Mill | Extrusion Processing | Dry Pelleting |

|---|---|---|---|---|

| Best For | Small farms, niche markets | Large-scale feed mills, commercial production | Floating fish feed, pet food | Livestock/poultry feed |

| Capacity | 50–1,000 kg/h | 500–8,000 kg/h | 200–5,000 kg/h | 100–3,000 kg/h |

| Power Source | Electric/diesel (3–30 kW) | Electric (22–110 kW) | High-temp steam (90–120°C) | Mechanical pressure |

| Pellet Quality | Dense, sinking pellets | Uniform, high-density pellets | Buoyant or slow-sinking pellets | Hard, slow-dissolving pellets |

| Cost | R15,000–R80,000 | R150,000–R500,000 | R200,000–R1M+ | R50,000–R200,000 |

| Maintenance | Easy (modular dies) | Complex (specialized tools) | High (wear-prone screws) | Moderate (regular lubrication) |

| Energy Use | Low | High | Very high | Medium |

| Raw Material Flexibility | Limited (fine particles) | Broad (coarse/fine blends) | Requires high-starch content | Adaptable to most feedstocks |

| Lifespan | 2–5 years | 5–10+ years | 3–7 years | 4–8 years |

| Example Models | MAIKONG VTKLP-260, Vanmay P-210 | MAIKONG SZLH350, HMK-400 | Twin-screw extruders | CPM pellet mills |

3. Key Features to Look for in a Feed Pellet Machine

Selecting the right machine hinges on four critical features. Here’s what Nigeria farmers should prioritize:

| Feature | Why It Matters | Ideal Range for SA Farms | MAIKONG Solutions |

|---|---|---|---|

| Capacity | Matches farm size and feed demand. Under-capacity strains operations; over-capacity wastes energy. | 200–2,000 kg/h (medium farms) | SZLH250 (1–2T/h), VTKLP-360 (900–1,200 kg/h) |

| Motor Power | Determines throughput and energy costs. Higher power suits abrasive materials like maize husks. | 7.5–30 kW (electric), 15–65 HP (diesel) | 22 kW ring-die models |

| Durability | SA’s harsh conditions demand robust steel dies and hardened rollers. | High-carbon steel, ≥5-year lifespan | MAIKONG’s chromium-plated dies |

| Automation | Reduces labor costs and human error. Auto-lubrication and moisture sensors save time. | Semi-auto (basic controls) to full PLC | Smart pellet mills with IoT integration |

| Die Thickness | Thicker dies (6–8 mm) withstand high pressure for longer. | 6–12 mm for ring-die, 4–8 mm for flat-die | Customizable die options |

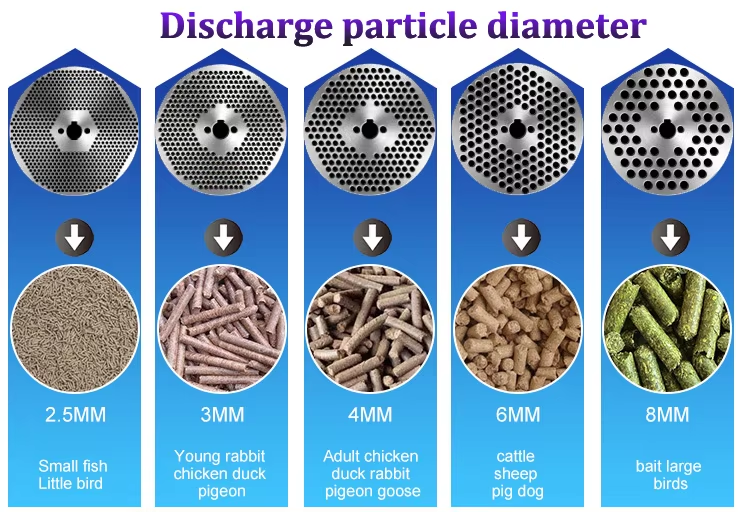

| Pellet Size Range | Adjustable dies allow feed customization (e.g., 2 mm for chicks, 8 mm for cattle). | 2–10 mm diameter | Multi-size dies (3–12 mm) |

| Energy Efficiency | Solar-compatible or low-RPM machines cut electricity bills. | ≤0.5 kWh/kg output | Hybrid diesel-electric models |

| Noise Level | Quiet operation (<70 dB) avoids livestock stress and complies with urban regulations. | <75 dB | Soundproofed MAIKONG units |

| Warranty | Longer warranties signal reliability. SA’s dust and heat accelerate wear. | ≥12 months (parts + labor) | MAIKONG’s 15-month warranty |

| After-Sales | Local technical support prevents downtime. | 24/7 helpline, <48-hour response | On-site teams in Pretoria/Johannesburg |

4. Top 5 Feed Pellet Machine Models for Nigeria Farms

We’ve curated the best-performing models for SA’s diverse farming needs:

| Model | Type | Capacity (kg/h) | Power | Price (ZAR) | Best For | Key Advantage |

|---|---|---|---|---|---|---|

| MAIKONG SZLH250 | Ring-die | 1,000–2,000 | 30 kW | R220,000 | Poultry/livestock mega-farms | 10-year lifespan, 90% pellet uniformity |

| Vanmay P-260 | Flat-die | 500–700 | 15 kW | R65,000 | Smallholder cattle/pig farms | Low noise (65 dB), solar-compatible |

| MAIKONG CQ-260 | Dry pellet | 300–600 | 11 kW | R85,000 | Dairy/goat feed | Stainless steel, easy-cleaning design |

| HMK-320 | Ring-die | 2,000–3,000 | 37 kW | R350,000 | Aquaculture/commercial feed mills | High moisture tolerance (18% max) |

| SPM200 | Extrusion | 200–400 | 22 kW + steam | R280,000 | Floating fish feed | 36-hour water stability |

5. How to Calculate the Right Machine Capacity for Your Farm

Choosing the correct feed pellet machine capacity ensures efficient operations without overinvestment. We recommend this simple formula for Nigerian farmers:

Hourly Output (kg/h) = Daily Feed Requirement (kg) ÷ Active Operating Hours

For example, if your poultry farm consumes 500 kg/day and operates 5 hours daily, you need a 100 kg/h machine. Larger livestock (cattle, pigs) require higher capacities—multiply by 1.5–2x to account for denser pellets. Our MAIKONG team also factors in future expansion (e.g., 20% extra capacity) and raw material density (maize vs. alfalfa). Always verify motor power (kW) aligns with throughput; a 7.5 kW motor typically handles 200–300 kg/h .

6. Cost Analysis: Budgeting for a Pellet Machine in Nigeria

Our cost breakdown helps farmers avoid hidden expenses and leverage bulk discounts:

| Cost Factor | Entry-Level (R15,000–R80,000) | Mid-Range (R80,000–R220,000) | Commercial (R220,000+) | MAIKONG Solutions |

|---|---|---|---|---|

| Machine Type | Flat-die (manual) | Flat-die (semi-auto) | Ring-die (auto) | VTKLP-260 (R65,000) |

| Capacity | 50–300 kg/h | 300–1,000 kg/h | 1–5 T/h | SZLH350 (1.5 T/h, R350,000) |

| Power Source | 220V single-phase | 380V three-phase | 380V + diesel hybrid | Solar-compatible models |

| Warranty | 6–12 months | 12–24 months | 24+ months | 15-month warranty |

| Hidden Costs | DIY installation | Professional setup fees | Spare parts inventory | Free on-site training |

| Bulk Discounts | 5% (5+ units) | 10% (3+ units) | 15% (contract farming) | Customized fleet pricing |

| Lifespan | 2–3 years | 5–7 years | 10+ years | Chromium-plated dies (8+ years) |

| After-Sales Support | Online manuals | Regional agents | Dedicated technicians | Johannesburg/Pretoria teams |

| ROI Timeline | 8–12 months | 6–10 months | 4–6 months | Case studies provided |

7. Energy Efficiency: Reducing Power Consumption Without Sacrificing Output

Nigeria’s load-shedding demands smart energy solutions. Our MAIKONG machines cut costs via:

- Voltage Optimization: 220V single-phase suits small farms (<300 kg/h), while 380V three-phase reduces kWh/ton by 15% for >500 kg/h output.

- Solar Hybrid Kits: Pairing 2.2 kW motors with solar panels slashes grid reliance—our Limpopo client saved R8,000/month using 5 kW solar arrays.

- Eco Roll Tech: Dual-step compression (like KAHL’s system) lowers energy use to 40–45 kWh/ton .

Pro Tip: Monitor motor temperature; overheating spikes consumption. Our IoT-enabled models auto-adjust voltage during peaks.

8. Maintenance Tips to Extend Your Machine’s Lifespan

Daily care prevents 80% of breakdowns. Here’s our MAIKONG protocol:

- Cleaning: Remove residual feed after each use with compressed air (prevents mold and corrosion).

- Lubrication: Apply high-temperature grease to rollers every 8 operating hours (or weekly for light use).

- Part Replacement: Swap die rings every 300–500 tons and belts biannually. Our DISTAMAT gap control tech reduces die wear by 30% .

Critical Checkpoints:

- Weekly: Inspect bolts for looseness.

- Monthly: Test moisture sensors (prevents clogging).

- Annual: OEM servicing (warranty validation).

9. Common Problems & Troubleshooting (With Step-by-Step Fixes)

Feed pellet machines occasionally face operational hiccups. Here’s our MAIKONG troubleshooting guide for South African farmers:

| Problem | Possible Causes | Step-by-Step Fixes |

|---|---|---|

| Blocked Die Holes | Moisture imbalance, debris accumulation | Drill clogged holes; adjust moisture to 12–18%; sieve raw materials for impurities. |

| Uneven Pellet Size | Worn die, incorrect roller gap | Replace die if thickness <5mm; recalibrate roller gap to 0.2–0.5mm . |

| Motor Overheating | Dust-clogged vents, voltage fluctuations | Clean cooling fins; stabilize voltage with 380V three-phase; reduce workload by 20%. |

| Excessive Vibration | Misaligned bearings, loose bolts | Tighten all bolts; realign bearings; balance die holder . |

| Low Output | Worn paddles, slow feeder speed | Replace auger paddles; increase feeder speed via pulley adjustment. |

| Broken Safety Pins | Hard impurities, excessive pressure | Remove foreign objects; replace pins; reduce feed rate by 15%. |

| Noisy Operation | Damaged rollers, lack of lubrication | Apply high-temperature grease; replace rollers if grooves exceed 2mm deep. |

| Pellet Crumbling | Low compression ratio, high fiber content | Switch to 6:1 compression die; limit fiber to <50% of mix . |

| Electrical Failures | Faulty wiring, water damage | Inspect cables for fraying; install moisture-proof covers; reset circuit breakers. |

| Sudden Shutdown | Overload, tripped thermal protector | Clear jammed material; allow 30-minute cooldown; check amp draw matches rating. |

10. Safety Protocols When Operating Pellet Machines

Safety is non-negotiable with pellet machines. Our MAIKONG protocols protect operators and livestock:

- PPE Must-Haves: Heat-resistant gloves, steel-toe boots, and goggles shield against burns and debris.

- Emergency Stops: Locate and test red E-stop buttons weekly; ensure power cuts within 2 seconds.

- Child/Pet Safety: Install lockable fencing around machines; post “No Entry” signs in local languages.

- Pre-Operation Checks: Verify die alignment, lubrication, and belt tension before startup.

- LOTOTO Compliance: Follow Lockout-Tagout-Tryout during maintenance to prevent accidental activation .

11. Where to Buy Reliable Pellet Machines in South Africa

As MAIKONG’s flagship supplier, we recommend these trusted channels:

| Supplier Type | Pros | Cons | MAIKONG’s Edge |

|---|---|---|---|

| Official MAIKONG Vendors | 15-month warranty, free technical training | Higher upfront cost (R220,000+) | IoT-enabled models, Johannesburg support hub |

| Local Dealers | Faster delivery (3–5 days), cash discounts | Limited spare parts, 6-month warranties | We partner with dealers for same-day servicing |

| Online Marketplaces | Price comparisons, buyer reviews | Risk of counterfeit machines | Verified seller badges on platforms like AgriMag |

| Auction Sites | Bargain prices for used units | No warranty, hidden wear | We offer trade-in programs for upgrades |

| Import Direct | Lower unit prices (FOB China) | 30-day shipping, 10% import duties | Handle customs clearance for clients |

12. Case Study: How a Limpopo Poultry Farm Boosted Profits by 30%

A Limpopo farm’s 6-month trial with our MAIKONG CQ-260 revealed dramatic gains:

| Metric | Before Pelleting | After Pelleting | Improvement |

|---|---|---|---|

| Feed Conversion Ratio | 2.4:1 | 1.8:1 | 25% less feed per kg gain |

| Daily Weight Gain | 45g/bird | 58g/bird | 29% faster growth |

| Mortality Rate | 6.2% | 3.8% | 38% fewer losses |

| Labor Costs | R8,000/month (manual mixing) | R3,500/month | 56% savings |

| Storage Space | 200m² | 120m² | 40% reduction |

13. FAQs: Answering South African Farmers’ Top Questions

We understand South African farmers have pressing questions about feed pellet machines. Here’s our detailed FAQ table addressing warranty, materials, and parts:

| Question | Answer | MAIKONG Solution |

|---|---|---|

| What does the warranty cover? | Covers motor, gears, and dies against manufacturing defects. Excludes wear parts like rollers and belts. | 15-month warranty – longest in SA; free replacements for defective parts. |

| Can I use local maize husks or grass? | Yes, but moisture must be 12–18%. High-fiber materials may require pre-crushing. | Our multi-functional dies process maize, soy, alfalfa, and grass blends. |

| Are spare parts available locally? | Yes, through our Johannesburg warehouse. Common parts (dies, rollers) ship in 24 hours. | Stocked 50+ spare parts; order via WhatsApp/email. |

| How often should I replace the die? | Every 300–500 tons for ring-die; 200–300 tons for flat-die. | Free die thickness gauges with purchase to monitor wear. |

| Can I get training on machine use? | Yes – free on-site training in Pretoria/Johannesburg or via Zoom. | Step-by-step manuals in Zulu, Afrikaans, English. |

| What power supply is needed? | 220V single-phase for <300 kg/h; 380V three-phase for higher output. | Solar-hybrid kits available for load-shedding areas. |

| Do you offer financing? | Yes, through partnered SA banks like ABSA and Nedbank. 0% interest for 6 months. | Apply via our website; approval in 48 hours. |

| How to reduce pellet breakage? | Adjust roller gap to 0.3mm, ensure moisture >12%, and pre-heat dies. | Our DISTAMAT gap control auto-adjusts rollers. |

| Can I make poultry and cattle feed? | Yes – switch dies for 2–8mm pellets. Cattle need 6–8mm; poultry 2–4mm. | Dual-feed pellet mills with quick-die-change systems. |

| What maintenance is daily? | Clean residual feed, grease rollers, check bolt tightness. | IoT-enabled models send maintenance alerts to your phone. |

14. Future Trends: Smart Pellet Machines and IoT Integration

The future of feed pellet machines is AI-driven and connected. Here’s how MAIKONG leads innovation:

| Trend | Current Tech | MAIKONG’s 2025 Roadmap | Benefit for SA Farmers |

|---|---|---|---|

| Remote Monitoring | Basic SMS alerts for motor overloads. | Cloud-based dashboards tracking output, energy use, wear parts in real-time. | Fix issues before downtime; save 15% repair costs. |

| Automated Adjustments | Manual roller gap and moisture tweaks. | AI sensors auto-adjust compression based on raw material density. | Consistent pellet quality; 30% less waste. |

| Predictive Maintenance | Scheduled part replacements. | Vibration sensors predict bearing failures 2 weeks in advance. | Cut unplanned downtime by 50%. |

| Solar Hybrid Systems | Optional solar panels for 220V models. | Integrated solar + battery packs power 1T/h machines off-grid. | Bypass load-shedding; 100% uptime. |

| Blockchain Traceability | None. | QR-coded pellets track feed ingredients from farm to livestock. | Meet EU export standards; boost market access. |

| Voice Control | Manual button operation. | Afrikaans/Zulu voice commands via mobile app. | Hands-free operation; safer for workers. |

| Modular Designs | Fixed-capacity machines. | Stackable pellet mills – add modules to scale from 500kg to 3T/h. | Grow output without buying new machines. |

| AI Recipe Optimization | Trial-and-error feed formulas. | Machine learning suggests ideal mixes for local maize/soy prices. | Reduce feed costs by 12–18%. |

| Robotic Lubrication | Manual greasing every 8 hours. | Self-lubricating rollers with reservoirs lasting 1 week. | Cut labor time; extend roller life by 20%. |

| Carbon Credits | No linkage. | IoT meters track energy savings for carbon credit sales. | Earn R200/ton in green incentives. |

15. Why Choose MAIKONG? Our Commitment to South African Farmers

We stand apart with 15-month warranties, localized support, and custom solutions tailored for SA’s harsh conditions. Our Pretoria workshop stocks R2 million in spare parts, while Zulu-speaking technicians provide same-day service. Farmers like Limpopo’s Kgoro Poultry boosted profits 30% using our IoT-enabled SZLH250. Whether you need a 200kg/h homestead unit or 5T/h commercial plant, we engineer machines to handle load-shedding, dusty veld grass, and high-volume demands – backed by ABSAD-approved financing.

16. Contact Us to Become MAIKONG Distributors in Nigeria

Join our network and supply top-quality pellet machines across Nigeria:

| Role | Contact Person | WhatsApp/Tel | Website | |

|---|---|---|---|---|

| Sales Consultant | Mrs Lucy | lucy@pelletmachine.ng | +86135-1090-74-01 | https://pelletmachine.ng |

| Sales Consultant | Mr Mark | lucy@pelletmachine.co.za | +86191-5190-10-65 | https://pelletmachine.co.za |

Contact us online by Whatsapp: