pelleting machine price in nigeria ,animal feed pellet machine

Economic Value of Pellet Mill and Hammer Mill in Feed Production

May 6, 2025

Economic Value of Pellet Mill and Hammer Mill in Feed Production

-

Material Bulk density: The bulk density of the material don dey affect output directly. When you wan make same size pellets, if the material bulk density high for pellet making, the output go high and power consumption go small. But if e no be like dat, output go low and power consumption go high.

-

The Quality of the Pellet Machine As small pellet machinery don popular now, e don become easy to process powder feed become pellet feed. This kind pellet feed processing machinery dey sell for about 500−4000. The powder feed go gelatinize for high temperature and come out from film holes under roller pressure to make pellets. You fit adjust pellet size easily.

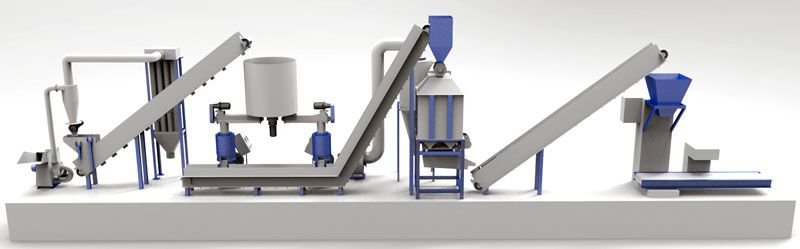

If you wan know more about feed pellet equipment details and feed pellet production line price, make you contact us! WS/TEL: 0086191-549010-65.

- Chemical composition of the material Amyloid: Different amyloid forms get different effects for pelleting. Raw starch particles surface rough, so e get strong resistance for pellet making. When raw starch content high, feed pellets output go low and pressing die go wear quick.

But ripe starch get these important properties:

- E turn to gel after conditioning to absorb water, and this gel help material pass mold hole well, make feed pellets production increase.

- The dried and cooled gel fit bond other components around am, make feed pellets quality better.

- During conditioning, starch particles dey sticky after steam cook and partly damage under feed pellet mill roller and die pressure, make feed pellets structure precise and quality better.

- Feed pellet making process no just depend on starch structure and properties, but also starch powder fineness.

- So when you use corn and sorghum as main pellet making materials, make you check grain size well before granulating.

Protein: Protein go deform when heat touch am, and bond strength go increase.

Oil volume: Oil and fat wey dey inside raw materials no go squeeze out during granulating temperature and pressure, so granulating effect no too much, but e affect yield and grease pellets quality well. If you add 1% fat inside material, pellets go soft small and production go improve well, die and roller wear go reduce. But if raw material oil content too high before granulating, pellets go loose. Make oil content before granulating no pass 3%.

Molasses: Normally you fit add less than 10%, e fit work as binder to make particles hard, but e depend on how material fit absorb molasses.

Fiber: Fiber no get bond by itself, but if fiber too much and resistance high, output go reduce and die go wear quick. Materials wey get high crude fiber content dey loose and porous inside, so you must control water well. If moisture too high with high temperature, pellets go expand quick and fit crack after coming out from mold.

Heat sensitive materials: When you dey add vitamins, seasonings and other heat sensitive materials for pelleting, reduce pelleting temperature, and no add excess, make sure these ingredients remain effective for finished product.

- Binders: Some fodder no get plenty starch, protein or other cohesive components, so e hard to make feed pellets. Because of dis, you need add binder make grains reach correct seed setting level.

What are the physical and chemical changes in protein, carbohydrates, fats, and vitamins in the granulation process?

Protein Physical change: Protein solubility go reduce, and different raw materials water solubility go differ under different granulation conditions because of their protein content. Generally, high water solubility protein concentration go reduce more than small water solubility protein.

Chemical changes: Protein go reduce small small, protein hydrolysis time for digestive tract go reduce, protein content for whole process go remain almost same, and amino acids stability and potency go reduce small.

Carbohydrates: Physical changes: Starch go absorb water begin dissolve and lose original crystal structure. Starch swelling temperature for different materials fit make starch reach gelatinization level wey high temperature extrusion require, this process fit also help conditioning to improve granulating and nutrition, this structure get protection ability and fit improve feeding effect.

Chemical changes: Besides starch production, starch also go hydrolyze, give better conditions for animal enzyme digestion. After granulation, feed hygienic index go good, almost no source contamination.

The change of fat: High temperature go make lipase stop working, reduce fat hydrolysis during storage, and improve stability. Fatty acids go protect lipoxygenase structure with branched cleavage, and reduce acidification speed.

Vitamin: Friction na main thing wey dey make vitamin unstable. E go destroy vitamin crystal layer and make plenty vitamins oxidize. Pressure go damage vitamin A and other fat soluble vitamins gel layer seriously.

For these last ten years, pellet feed don improve well for plenty countries. For USA, Japan, Spain, Germany and other countries, pellet feed dey about 60%-70% of compound feed. We fit expect more developments for shaped full-price feed production like pellets or briquetting! Fill the form below contact us, you go get more feed pellet information! WS/TEL: 0086191-549010-65.

Contact us online by Whatsapp: