pelleting machine price in nigeria ,animal feed pellet machine

How to Improve the Quality of Chicken Feed Pellets?

May 6, 2025

How to Improve the Quality of Chicken Feed Pellets?

Feed quality is crucial for providing proper nutrition to chicks, chickens, and laying hens, directly impacting breeding efficiency. Besides raw material quality and nutritional design, feed form significantly affects poultry performance. Chicken feed typically comes in two forms: mash feed and pellet feed. Pellet feed offers superior feeding results due to its unique processing method.

Advantages of Chicken Pellet Feed in Feeding Process

Pellet feed provides several benefits compared to powdered feed:

-

More Balanced Nutrition

- Uniform pellet size prevents nutrient separation during transport

- Reduces selective feeding and nutritional imbalances

-

Higher Feed Utilization Rate

- Chickens consume pellets completely, minimizing waste

- Lower powder content improves feed efficiency

-

Improved Palatability and Digestibility

- 70-85°C processing temperature cooks ingredients thoroughly

- Enhances taste and nutrient absorption

-

Enhanced Feed Safety

- High-temperature steam kills harmful microorganisms

- Provides effective sterilization and insect control

-

Reduced Nutrient Loss and Dust

- Minimizes trace element loss from uneven feeding

- Decreases dust during handling, improving farm environment

How to Make High-Quality Chicken Feed Pellets?

Producing quality pellets requires proper feed formulation, reliable pellet mills, and skilled operators. Key considerations include:

Chicken Feed Formulas and Storage

| Feeding Type | Pellet Feed Formula (%) |

|---|---|

| Growing Chickens | Corn 61.4, Wheat Bran 14, Soybean Meal 21, Calcium Hydrogen Phosphate 1.2, Stone Powder 1.1, Salt 0.3, Additives 1 |

| Adult Chickens | Corn 62, Wheat Bran 3.2, Soybean Meal 31, Calcium Hydrogen Phosphate 1.3, Stone Powder 1.2, Salt 0.3, Additives 1 |

| Laying Hens | Corn 62, Wheat Bran 3.2, Soybean Meal 31, Calcium Hydrogen Phosphate 1.3, Stone Powder 1.2, Salt 0.3, Additives 1 |

Note: These are sample formulas – adjust according to your specific needs.

Feed Storage Guidelines:

- Store in cool, dry, ventilated areas away from light and moisture

- Maximum storage duration:

- Summer: 3-5 days

- Winter: 5-7 days

- Never use moldy feed

Identifying Quality Chicken Feed:

- Taste Test: High-quality feed has pleasant flavor; poor-quality smells odd

- Texture Check: Rub pellets between fingers to assess size, hardness, and stickiness

Choosing Reliable Feed Pellet Equipment

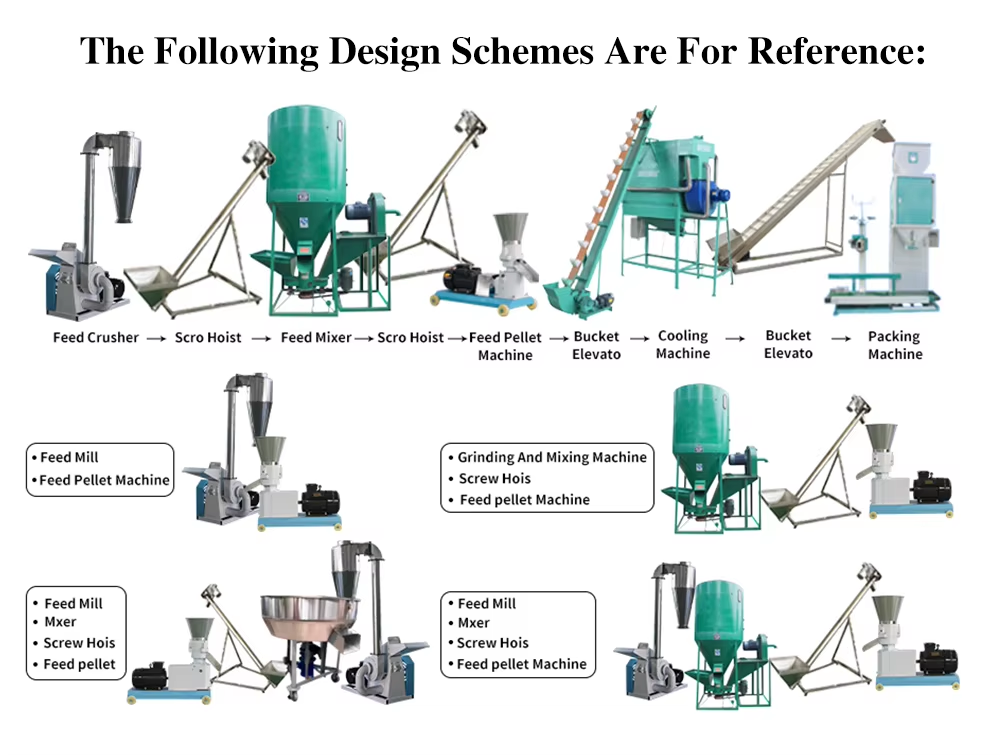

Selecting proper machinery ensures pellet quality and builds your reputation. MAIKONG offers:

- Durable pellet mills for consistent production

- Technical support for optimal operation

- Custom solutions for your specific needs

For equipment details and quotations, contact MAIKONG today! Our team responds within one business day.

Contact MARK for Assistance 📞 WS/TEL: 0086191-549010-65

Contact us online by Whatsapp: