pelleting machine price in nigeria ,animal feed pellet machine

How are Dairy Cow Feed Pellets Processed?

May 6, 2025

How are Dairy Cow Feed Pellets Processed?

The pellet feed for dairy cows is scientifically formulated according to the concentration of nutrients required at each stage of its growth. A variety of feed materials, including coarse feed, concentrated feed, and feed additives, are crushed with a grinder, mixed with a mixer, and then processed into pellets using a pellet machine. Common raw materials for dairy cow feed pellets include high-quality alfalfa grass, full-fat expanded soybeans, whole cotton seeds, corn, bran, soybean meal, wheat, and more.

MAIKONG Machinery is a comprehensive animal feed pellet equipment manufacturer specializing in process design, technology research and development, manufacturing, sales, and after-sales service. If you want to understand the technological process of livestock feed pellets, learn about the production process of dairy cow feed pellets, or select the right equipment, contact us today! Our professional team is ready to guide you.

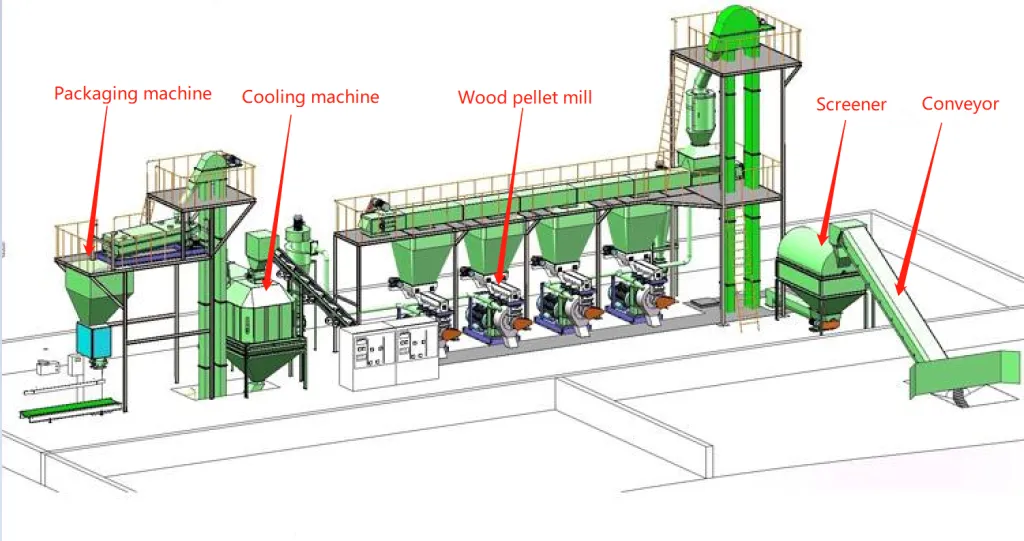

Processing Technology of Dairy Cow Feed Pellets

The complete set of equipment for dairy cow feed pellets mainly consists of six parts:

- Raw material receiving machine

- Corn crushing machine

- Ingredient mixing machine

- Finished product discharging system

- Computer control system

- Dust removal system

Production Process Overview

- Crushed corn and other raw materials are stored in their respective batching bins via a conveyor.

- The pre-stored formula in the computer is selected, and the system automatically measures the required amounts of each raw material.

- The materials are mixed thoroughly in the mixer.

- The mixed feed is transported to the finished product warehouse for storage.

- Coarse feed and concentrated feed are blended in the mixing tank to complete the pellet production process.

For reference photos, detailed equipment lists, or cost estimates, feel free to inquire!

Small Feed Mill Plant Technical Parameters

| Model | Power (kW) | Capacity (kg/h) | Weight (kg) | Dimensions (mm) L×W×H |

|---|---|---|---|---|

| STLP300 | 38.4 | 600–800 | 1700 | 7340 × 2360 × 4000 |

| STLP400 | 56.1 | 800–1000 | 2100 | 7445 × 2945 × 4000 |

Advantages of Pellet Feed for Dairy Cows

- Even Mixing & Balanced Nutrition

- Ensures uniform nutrient distribution, preventing selective feeding.

- Improved Palatability & Feed Intake

- Kills harmful bacteria during processing while promoting probiotic growth for better nutrient absorption.

- Enhanced Health & Immunity

- Reduces gastrointestinal diseases by over 90% and lowers the risk of epidemics.

- Faster Growth & Higher Efficiency

- Customized formulas for each growth stage increase daily weight gain and shorten the slaughter period.

Feed Formulas for Different Stages of Dairy Cattle Breeding

1. Feed Formula for Calves

- Colostrum: Must be given within 1–2 hours after birth (≥1 kg).

- Lactation: Daily intake of 10–15 kg milk.

- Weaning: Starts at 7 days with concentrate and soft green fodder; weaning occurs at 0.75–1.0 kg/day (around 8 weeks).

2. Feed Formula for Growing Cattle

- Protein: 13–14% (2–2.5 kg concentrate/day).

- Roughage: Medium-quality hay to improve rumen function.

3. Feed Formula for Young Cattle

- Protein: 12% (2.5 kg concentrate/day).

- Dry Matter Intake: Controlled at 11–12 kg/day.

4. Feed Formula for Adult Cows

- Dry Period: High-quality hay (≤2.5 kg concentrate).

- Perinatal Period: Gradual increase in concentrate (max 1% of body weight).

Start Your Dairy Cow Feed Pellet Business with MAIKONG!

Looking to produce high-quality, nutritious dairy cow feed pellets? MAIKONG offers hot-selling pellet machines and complete production line solutions. Whether you’re in Nigeria, Ghana, Tanzania, or Egypt, we provide cost-effective setups and business guidance.

Contact MARK today for a customized plan!

- WS/TEL: 0086191-549010-65

Contact us online by Whatsapp: