pelleting machine price in nigeria ,animal feed pellet machine

How Many Steps From Raw Materials to Feed Pellets?

May 6, 2025

How Many Steps From Raw Materials to Feed Pellets?

Many poultry and livestock farmers, as well as those planning to start feed production businesses, frequently ask MAIKONG professionals: “How exactly does feed processing equipment turn raw materials into pellet feed? What are the required technological processes and machinery needed?”

The answer varies depending on the scale of operation:

- A small feed processing unit may fit in one medium-sized truck

- A large-scale feed plant may require multiple containers for equipment transportation

Modern Feed Production Basics

Today’s animal feed primarily consists of protein and energy sources, available in three main forms:

- Mash feed (powder form)

- Pellet feed

- Wet mix feed

While mash feed units exist, pellet feed production has gained popularity due to its efficiency and convenience. The pelletizing process itself is straightforward, though some operations use more equipment for higher automation levels.

Standard Feed Pellet Production Process

1. Basic Equipment Setup

A simple feed processing line includes:

- Grinding system – Reduces raw material size

- Mixing system – Ensures uniform ingredient distribution

- Conveying system – Transports materials between stages

- Pelletizing system – Forms the final pellets

- Auxiliary equipment – Includes storage bins, racks, etc.

2. Enhanced Production Lines

As automation advances and quality demands increase, additional steps are incorporated:

✅ Pre-Cleaning Stage (Before Grinding) Removes impurities using:

- Permanent magnet cylinders (for metal removal)

- Z-shaped iron separators

- Initial cleaning screens

✅ Dust Control Optional pulse dust collectors maintain air quality during crushing.

✅ Mixing Stage

- Crushed materials move via screw conveyor to mixers

- Fat/oil addition (max 3% to avoid pellet formation issues)

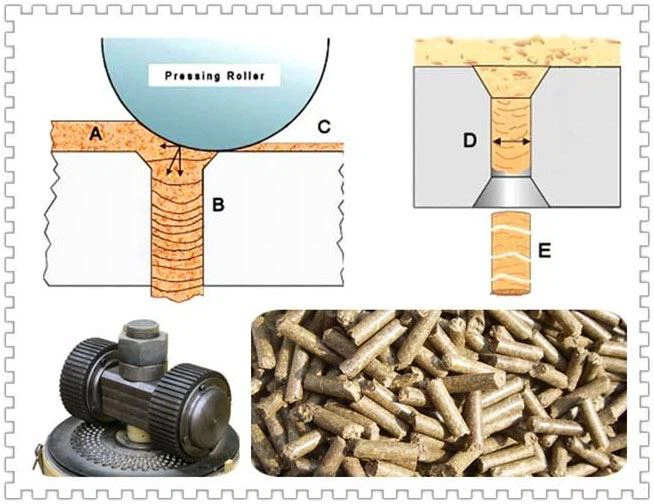

✅ Pelletizing Options

- Flat die pellet mills – Simple, cost-effective

- Ring die pellet mills – Allow conditioner/forced feeder attachments for premium quality

✅ Post-Pelletizing (For Commercial Plants)

- Bucket elevators transport finished pellets

- Additional equipment may include:

- Counterflow coolers

- Crumbler machines

- Grading sieves

- Automatic packing systems

Beyond Animal Feed

Modern feed processing equipment has diversified into:

- Sawdust pellet production

- Cat litter manufacturing

- Pet food processing …and other granule-based products

Need Feed Pellet Equipment? Contact MAIKONG Today! 📞 WS/TEL: 0086191-549010-65 🌐 Your trusted partner in feed production solutions

Upgrade your operation with MAIKONG’s reliable machinery – where quality meets affordability!

Contact us online by Whatsapp: