pelleting machine price in nigeria ,animal feed pellet machine

How to Choose Equipment for Setting Up a MAIKONG Feed Mill Plant

May 6, 2025

How to Choose Equipment for Setting Up a MAIKONG Feed Mill Plant

For small and medium-sized livestock and poultry feed mills, the standard production process includes:

- Raw material receiving

- Crushing

- Batching

- Mixing

- Granulating

- Cooling

- Screening

- Finished product packaging

The core equipment includes:

- Crusher

- Mixer

- Pellet mill

Choosing the right equipment is critical for feed quality and production efficiency.

1. Feed Crushing Machine Selection

Crushing breaks down solid materials into smaller particles, improving digestibility and processing efficiency.

Why Crushing Matters:

✅ Better digestion – Smaller particles help animals absorb nutrients faster ✅ Uniform mixing – Prevents ingredient separation ✅ Improved pellet quality – Affects durability and water stability (important for fish feed) ✅ Higher feed conversion rate – Reduces waste in animal waste

Recommended Crusher: MAIKONG SFSP Hammer Mill

✔ High efficiency – Cuts feed into 40-60 mesh size (ideal for poultry, pig, cattle, sheep feed) ✔ Low noise & vibration – Large diameter, slow-speed design ✔ Easy maintenance – Quick screen replacement, tungsten carbide hammers (lasts 7-8x longer) ✔ Safety features – Auto-shutoff when door opens

Pro Tip: Use a centrifugal fan with the crusher to:

- Reduce dust

- Improve crushing speed by 10-15%

- Lower moisture for better storage

2. Feed Mixing Machine Selection

Mixing ensures all ingredients (including vitamins & medicines) are evenly distributed—critical for animal growth.

Key Mixer Requirements:

✔ Mixing uniformity – Less than 10% variation (5% for premixes) ✔ Fast mixing time – Affects production speed ✔ Low residue – Less than 1% left in machine (0.8% for premixes)

Recommended Mixer: MAIKONG Twin-Shaft Paddle Mixer

✔ Mixes gently – No ingredient separation ✔ Faster blending – Fluidized zone improves mixing speed ✔ Easy cleaning – Prevents bacteria buildup

Maintenance Tip:

- Replace seals regularly to prevent leaks

- Clean mixer walls to avoid mold

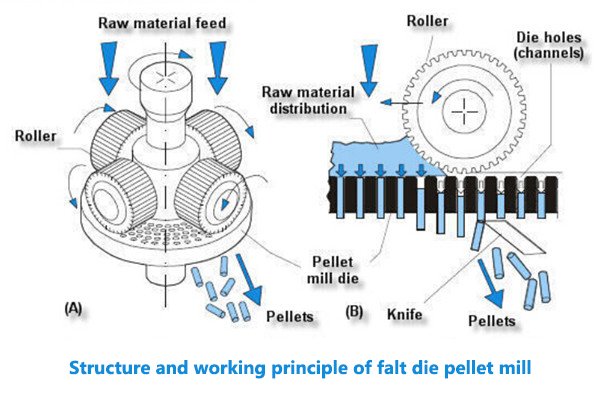

3. Feed Pellet Mill Selection

Pelletizing improves feed digestibility, reduces waste, and makes storage easier.

Benefits of Pellet Feed:

✅ Higher digestibility – Heat & moisture activate nutrients ✅ Prevents animal pickiness – Stops selective eating ✅ Reduces waste – 8-10% less feed loss ✅ Kills salmonella – Steam conditioning eliminates bacteria

Recommended Pellet Mill: MAIKONG Ring Die Pellet Machine

✔ High output – Smooth, uniform pellets ✔ Energy-efficient – Belt-driven models save power ✔ Better pellet quality – Durable, less dust

Operation Tips:

- Conditioning is key – Use dry steam (4-8 bar pressure)

- Check moisture & temperature – Ideal: 75-95°C, 15.5-17% moisture

- Cool pellets properly – Prevents cracking or mold

Case Study: A Feed Mill Mistake & Solution

A feed mill in Xinjiang, China skipped installing a dust collector & fan to save costs. Later: ❌ Low crushing speed – Couldn’t keep up with mixer & pellet mill ❌ Bottleneck in production

Solution: They added a dust collector + centrifugal fan, which: ✔ Boosted crushing efficiency ✔ Matched production speed

Lesson:

- Front-end equipment (crusher) should be 20-30% faster than later stages

- Don’t cut corners – Proper equipment ensures smooth operation

Conclusion

Choosing the right MAIKONG feed mill equipment ensures: ✔ Higher efficiency ✔ Lower maintenance costs ✔ Better feed quality

Need Help Setting Up Your Feed Mill? 📞 Call MAIKONG Now: WS/TEL: 0086191-549010-65 🌍 Free consultation for Nigeria, Uganda, Zambia & more!

Contact us online by Whatsapp: